INJECTION MOLDING

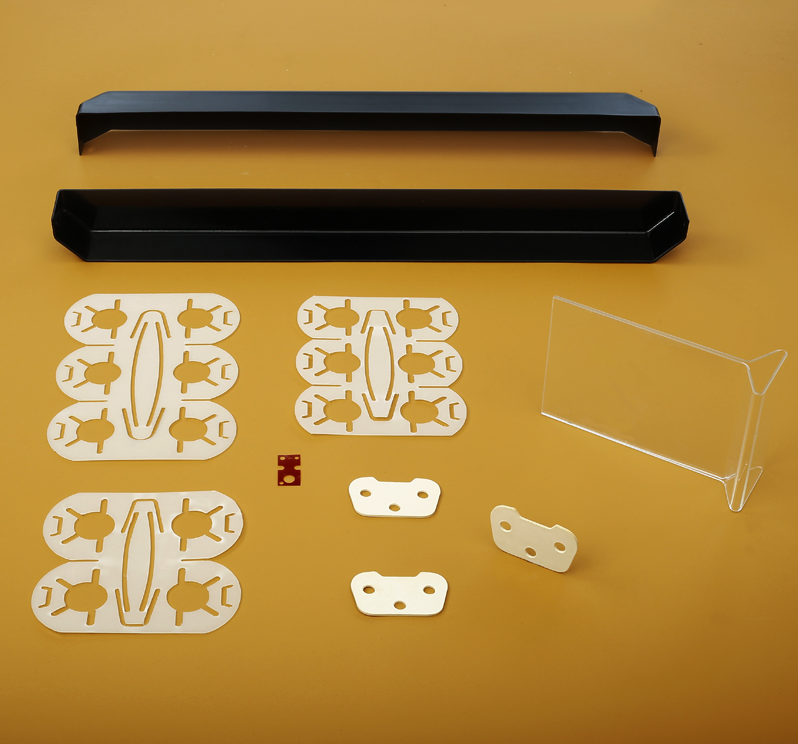

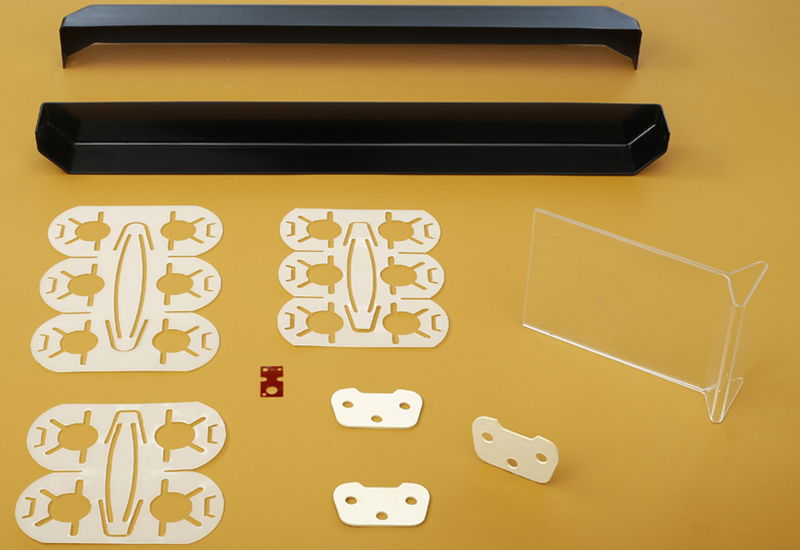

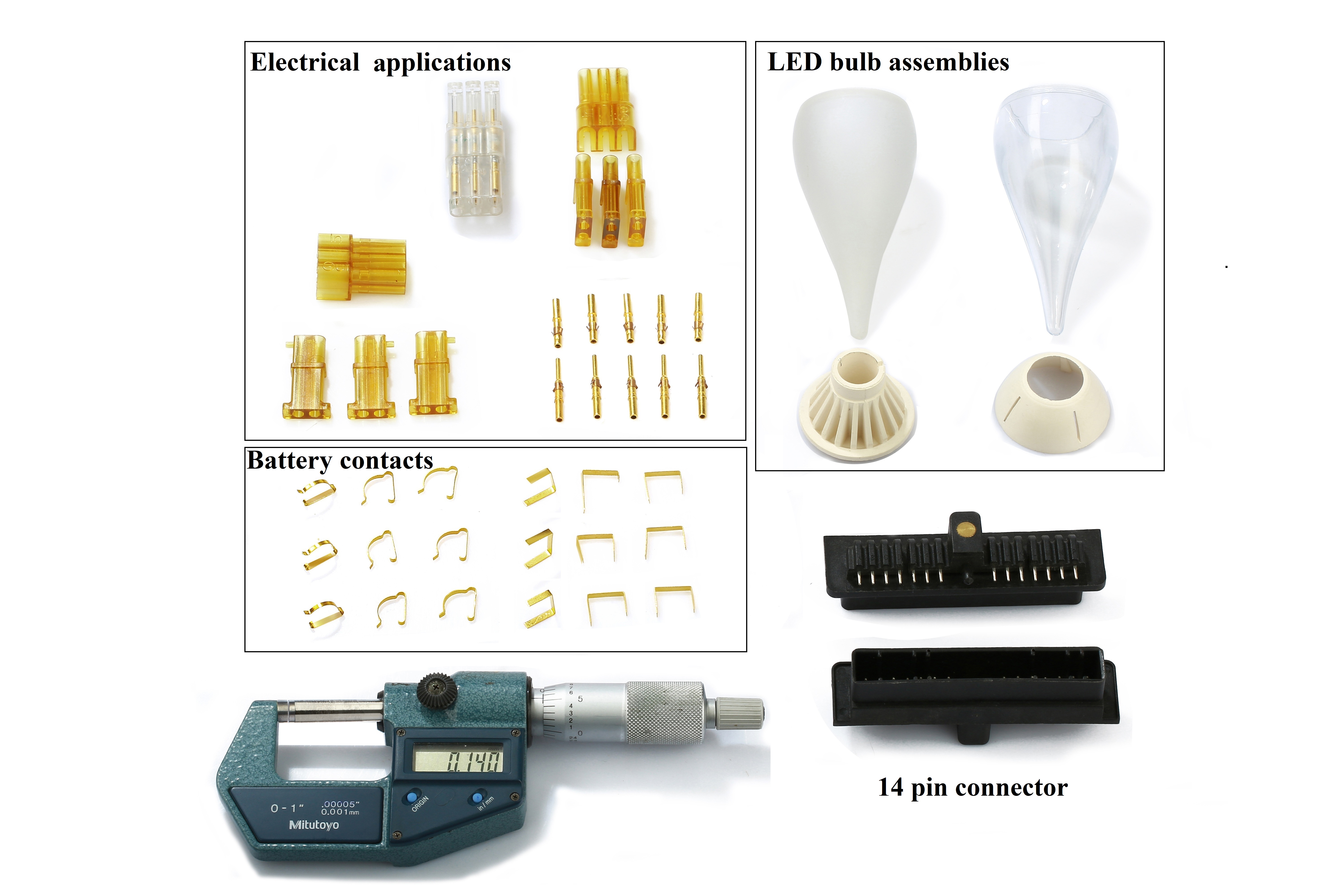

Specializing in close-tolerance injection molding of small and big plastic parts, we provide a total concept solution from design and tooling to production, fulfillment, and packaging. The combined effort of our designers and toolmakers results in molds that ensure quality, precision tolerances, and optimized cycle times. We have the capacity to mold parts with complex geometries. We have moulded parts ranging from 0.4 grams to 2.5 kilograms. We use entire range of plastic raw material whether it may be commodity plastic like PP, HDPE and LDPE OR engineering plastics like ABS, Nylon, GF nylon, PC, Polyester, and Delrin. The hi-tech engineering plastic like Ultem, PEK etc. are also used which are complex in molding and demand very good experience as well as quality molding machines using mold temperature controller (MTC).